In this article, we will continue to use the details regarding the definition of the current situation and goals.

To gather proper requirements for planning, we need to specify the requirements e.g. define the periods, processes and cycles of the scheduling objectives.

Since the items above are too broad, add or change them according to your needs.

Then define the requirements for the system.

To have more clarity on roles, define also the relationships with the external systems. At this stage, it is also often difficult to make final decisions. In such cases, please take one step further and verify the prototype.

The analysis also becomes easier if the necessary data and input/output are specified.

In addition, we need to define the requirements for the orders, master data and the results.

Make sure to align them with the contents of the “Diagnostic sheet” and their influence to future results.

If there is a need to define requirement for other items, you may just add a new sheet and define them.

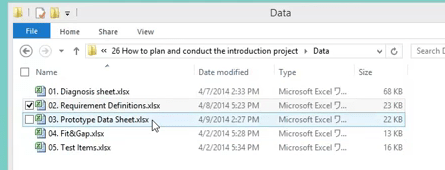

Now, we create the prototype.

We will be needing the data about the BOM of each item, manufacturing processes, working shifts and calendars, orders and inventories.

You may refer to the Diagnostic sheet for the items which production is to be scheduled.

To make the verification process smoothly running, we suggest to start with a small amount of data.

To study how to create prototypes and input the data into Asprova, please refer to the previous articles: “How to make a prototype” and “User interface”.

After the prototype is created and the data is specified, check them for their conformance to the requirements.

- Whether or not orders were registered as thought.

- Whether or not operations are displayed as wanted.

- Whether or not the mesh of the operations is too narrow.

- Whether or not the scheduling results are the same as expected.

- Whether or not the actual results can be reflected as thought.

- Whether or not system cooperation works as expected.

Pay special attention to the mesh of the operations because it affects the complexity of scheduling and the whole system, so the mesh must not be too fine. The appropriate mesh of the processes is the target processes of the work instructions.

If it is not possible to implement with standard features, you can opt to do manual adjustments or the development of additional programs. Otherwise, avoid it.

To learn more about Asprova specific to this sample demonstration, you may visit Asprova’s online help and its e-Learning videos at http://lib.asprova.com/ (see 26.How to plan and conduct the introduction project.).